Many of us have heard of hazmat training. However, few who are not in related industries are aware of what precisely hazmat means. This can be problematic if it means companies and professionals overlook the importance of seeking hazardous materials training to avoid accidents and other incidents in the workplace.

Warehouse Safety Tips for Handling Hazardous Materials

Essentially though it is very simple. The term hazmat, or HazMat, simply being an abbreviation of hazardous materials. Also known as ‘dangerous goods’, hazmat includes any goods that require specially trained personnel in order to handle due to their dangerous nature, Therefore, the need for hazmat training.

In this post, we will take a look at what hazmat training involves, and what you need to know when working in a warehouse.

Understanding Hazardous Materials and the Related Training

These can be solids, liquids, or gasses that are in some way harmful including materials that are flammable, explosive, asphyxiating, flammable, radioactive, poisonous, corrosive, acidic, bio-hazardous or allergenic among others. This might mean they are dangerous to the people handling them, to other living organisms (for example oil slicks can be harmful to sea life), to property or to the environment. Hazmat training therefore should not only keep the professional safe but also prevent accidents that could have an impact on the world around them.

The idea of hazmat training then is to try to limit the damage done to people and the surrounding area by teaching those handling them to take certain precautions.

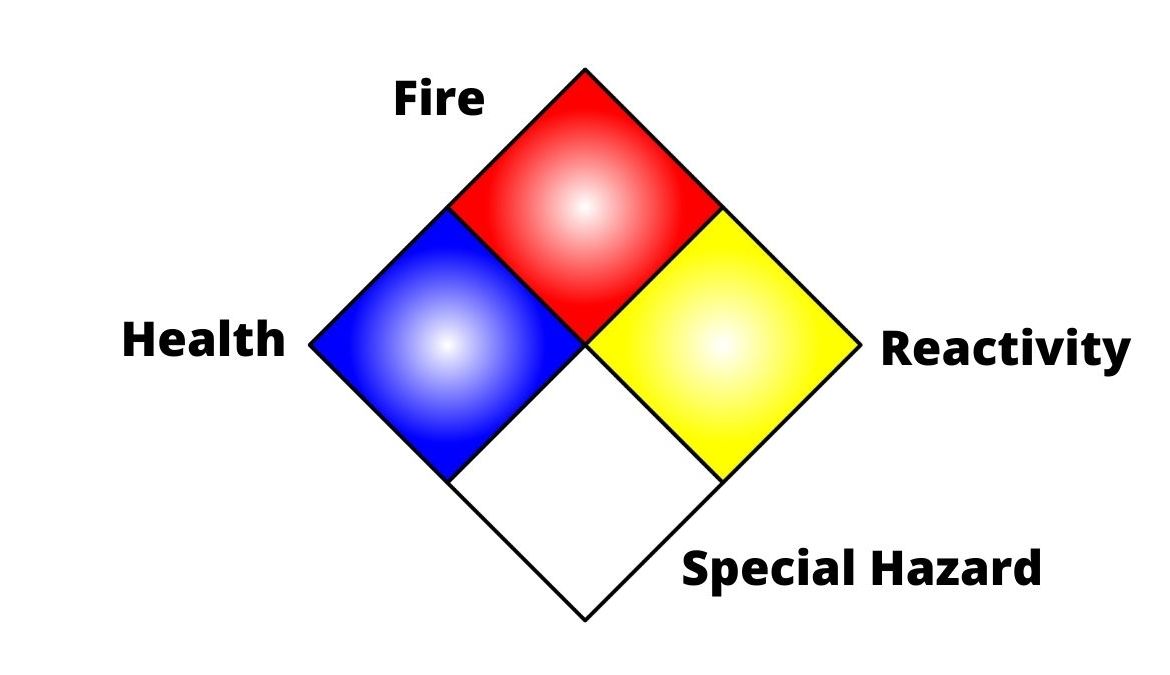

The Diamond Scale

Hazmat training explains a Hazmat as falling somewhere on a diamond scale which describes the nature of the material and why it is dangerous. Here red denotes that the material is flammable, orange that it is explosive, green that it is a safe gas, yellow that it is oxidizing, etc. This system is quite comprehensive and can even be used in a more complex way to describe interactions between a combination of hazardous materials; for example mixing red (flammable), with yellow (gas) = orange (explosive). This system was developed in France and is still taught in hazmat training today.

If you will be handling hazardous materials, then familiarizing yourself with this system is useful and important advice.

Hazmat training also involves learning to use specific safety precautions in storage, transport, and handling of materials. This means wearing protective equipment such as protective suits and gas masks. Often those who deal with hazardous materials are also subject to careful monitoring and surveillance to ensure that they remain healthy and not contaminated, for example by radioactive materials. There are also many laws involved in the use of hazardous materials that need to be understood before they can be used.

Again, this is training that you should seek out if you know you will be working with hazardous materials:

- Learn the safety equipment you need to use

- Familiarize yourself with any related laws

- Understand commonly used symbols and signs

- Read about the diamond system

General Precautions

There are also general precautions you can take that will help you to better avoid injuries and accidents.

For example:

Make sure that you take regular breaks when engaging in physically demanding work

- Don’t work if you are very tired, stressed, unwell, or otherwise distracted

- Use checklists: checklists are powerful tools that have been shown to be highly effective at reducing the incidence of mistakes in the workplace.

- These prevent us from being complacent and overlooking important precautions.

- Check the environment for potential hazards. These might include slip hazards, missing railings, etc.

- Always work with a partner if possible. You should only carry heavy objects if you have assistance from someone else.

Many of us assume that accidents are most common during particularly tricky maneuvers: when lifting a heavy crate filled with something highly breakable or potentially harmful, for example. In fact, though, this is generally untrue.

Rather, the most common accidents tend to occur when we become complacent: when we are carrying out work that we have done a thousand times before. They often happen because we are tired or overworked, often toward the end of the day.

This is because we are usually most vigilant precisely when we are working on those most difficult tasks. It’s the work in between that you need to be very careful of!

Ship Fortress LLC | Best Reefer Truckload | 3PL Warehouse Facility & Logistics in Milwaukee

Ship Fortress in Milwaukee understands every business has its own specific requirements. We customize and create solutions to meet each business unique needs. We truly do provide our clients with

- cost-effective delivery services

- flexible

- high-quality logistics solutions & LTL services

As a seamless extension of our clients’ business, we have a passion for exceptional customer service. Our experience and expertise allow us to provide multiple layers of client support services to propel businesses forward. Contact us for a FREE Quote.