Cross-docking is a practice in logistics that has received a lot of attention as of late. If you own and operate a distribution center or if you manage a shipping company, you’ve probably heard the term before. However, you’re probably wondering what exactly cross-docking is, and when it should be used. To learn more about this practice, keep on reading.

When Should Cross-Docking be Used?

What is Cross-Docking?

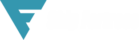

Cross-docking involves transferring products and goods from inbound carriers to outbound transport vehicles with the materials never having to move inside a warehouse for storage. The term quite literally describes the freight bypassing the warehouse, and rather “crossing the docks”, as the products are transferred from the receiving docks right to the shipping dock for outbound transport.

In other words, the cross-docking process means goods are never stored in a storage facility or warehouse. Instead, goods are transferred from inbound to outbound to be shipped out directly to retail establishments. This logistics practice might sound simple, but it’s actually a lot more complex than it seems. The rhythm and harmony between receiving and delivery activities are essential. When done properly, cross-docking can substantially minimize the distribution costs that are related to logistics.

There are four primary functions involved with warehousing and storage:

- Receiving

- Storage

- Collecting orders

- Sending goods

Of all four functions, storage and collecting orders cost the most. As such, when companies begin to cross-dock, notable amounts of money can be saved in storage costs especially.

Types of Cross-Docking

There are several different types of cross-docking solutions, which include:

Manufacturing cross-docking

Manufacturing cross-docking includes the receipt by the production of purchased and inbound goods; warehouses can receive products and prepare subsets for manufacturing orders.

Cross-docking distributor

Cross-docking distributor consolidates incoming goods from different suppliers into a mixed palette of products that are then shipped to the consumer when the final item is received. For example, car part distributors could obtain and combine parts from different suppliers and send them in one shipment.

Cross-docking retail

Cross-docking retail involves receiving and sorting goods from several suppliers for several retail stores on outbound trucks.

Transportation cross-docking

Transportation cross-docking combines shipments from several carriers in less-than-truckload (LTL) and the small package sectors for economies of scale. Transport from a variety of carriers are combined.

When to use Cross-Docking

So, when should cross-docking be used? It really varies and depends on several factors; however, the following are some instances when cross-docking services would be worthwhile:

- You’re short on time. Deliveries are running late and have to get to the retailer quickly. Cross-docking services would be a highly efficient way to do just that.

- The load you’re carrying is much too high; drivers are over-extended or last-minute additions were made, perhaps.

- Time-sensitive items need to be delivered, such as temperature-specific goods or other perishable products.

- Transportation costs are high and need to be reduced, in which case cross-docking would allow you to consolidate and save on transportation expenses.

BENEFITS

Is it right for you? It all depends on your business goals. Below is a breakdown of the benefits:

- Reduced labor costs – eliminate the “pick” in pick, pack, and ship, saving valuable time in the order lifecycle. Since the product is coming directly from the manufacturer or wholesaler (ready to ship), there’s no need to replenish inventory inside the warehouse.

- Reduced warehouse footprint – retailers that want to free up space or that have a limited warehouse footprint. Since that item isn’t in stock, it’s not sitting on the warehouse floor taking up valuable space – and possibly costing you money.

- No inventory ownership – When you cross-dock, the product enters the facility, gets scanned, then heads back out. This eliminates the need to hold inventory of the item, set up reorders, pay vendors for bulk orders, or track the SKU for shrinkage or damage. In this case, inventory is owned by the sending company only!

- Easier for bulk orders – Are you selling items in lots? If so, it’s much easier to have them packaged, labeled, and ready to ship at the dock than it is to pick and assemble items before shipment.

Ship Fortress LLC | Best Reefer Truckload | 3PL Warehouse Facility & Logistics in Milwaukee

Ship Fortress in Milwaukee understands every business has its own specific requirements. We customize and create solutions to meet each business’s unique needs. We truly do provide our clients with

- cost-effective delivery services

- flexible

- high-quality logistics solutions & LTL services

As a seamless extension of our client’s business, we have a passion for exceptional customer service. Our experience and expertise allow us to provide multiple layers of client support services to propel businesses forward. Contact us for a FREE Quote.